|

Adhesives

Physically hardening adhesives

Drying Adhesives Drying Adhesives

Technology

They are made of polymers dissolved in solvent (Polychloroprene, Polyurethane) or dispersed in water (white glue based on PVA (Polyvinyl acetate, cellulose, casein, polyvinyl alcohol or polyvinyl pyrrolidone composition).

Bonding process

The setting process of bonding is obtained by solvent evaporation, water evaporation or coalescence (When water or solvant is evaporated, the polymers’molecules become closer and closer until to form a continuous film adhesive) of a water based dispersion polymer.

Applications

Depending on the chemical composition of the adhesive, they will adhere to different materials to greater or lesser degrees. These adhesives are typically used for cellulosic supports (paper, cardboard and wood) or household applications.

Contact Adhesives Contact Adhesives

Technology

They are made of Natural Rubber and polychloroprene (Neoprene).

Bonding process

They must be applied to both surfaces and allowed some time to dry before the two surfaces are

pressed together. Once the surfaces are pushed together, the bond forms very quickly, hence, it is usually not necessary to apply pressure for a long time. So there is no need to use clamps.

Applications

Contact adhesives find use in furniture and footwear Industries.

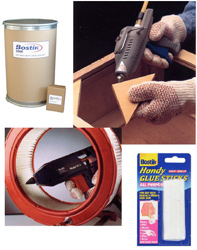

Hot Melt Adhesives

Technology Technology

These solventless adhesives are based on thermoplastic materials. A thermoplastic is a

polymer that turns to liquid when heated and freezes to a solid upon cooling

Bonding process

The hot-melt adhesive is heated and applied in its liquid state with the aid of glue guns or nozzles and the bonding is obtained in few seconds by cooling.

Applications

Hot melt adhesives are used in packaging, book binding, textiles, footwear and furniture, automotive, electronic industries.

Pressure Sensitive Adhesives (PSA) Pressure Sensitive Adhesives (PSA)

Technology

Pressure Sensitive is a term commonly used to designate a distinct category of adhesives based on elastomeric materials, such as Styrene Block Copolymers, which in dry form are permanently tacky at room or low temperature.

Bonding process

This adhesive forms a bond when pressure is

applied to marry the adhesive with the substrate.

Applications

Pressure sensitive adhesives are designed for both permanent or removable applications and some high performance permanent PSA exhibit high adhesion values. They are used in pressure sensitive tapes, labels, note pads, automobile trim, and a wide variety of other products.

Chemically hardening adhesives

Polyurethane Adhesives Polyurethane Adhesives

Technology

Polyurethanes adhesives are based on Polyisocyanates and Polyether / Polyester Polyols chemistry. They are available in one or two components systems.

Bonding process

The one component adhesive (PU1K) reacts with air humidity and can be applied at room temperature (PUR) or at high temperature like a hot-melt adhesive (HMPUR). The two components adhesive (PU2K) needs to be mixed according specific ratio before use.

Applications

They find use in Industrial Assembly, flexible packaging, windsceen bonding.

Epoxy Resin Adhesives Epoxy Resin Adhesives

Technology

Epoxy adesives are a major part of the class of adhesives called “structural adhesives". As for the polyurethanes, they can be one or two components systems.

Bonding process

The one component epoxy needs to be cured at high temperature, whereas the two components epoxy bond at room temperature. They can be made flexible or rigid, transparent or opaque/colored, fast setting or extremely slow setting.

Applications

These high-performance adhesives are used in many applications (transportation, golf clubs, skis, snow boards, household) where high strength bonds are required.

Anaerobic Adhesives Anaerobic Adhesives

Technology

anaerobic adhesives based on diacrylate chemistry are single-component adhesives that harden rapidly to form a strong bond between surfaces from which air is excluded.

Bonding process

Oxygen is an inhibitor for anaerobic adhesives. In the presence of oxygen in air, the product does not react and stays liquid. These two following conditions are needed for proper cure:

- Contact with a metal surface.

- Absence of oxygen or air.

Applications

They are recommended for use on metal surfaces, for threadlocking of nuts and bolts

Cyanoacrylate Adhesives Cyanoacrylate Adhesives

Technology

Cyanoacrylate adhesives are one-part acrylate adhesives often called “Super glues®”.

Bonding process

Cyanoacrylate adhesives cure instantly on contact with mated surfaces through a reaction with surface moisture (anionic polymerisation).

Applications

They are used in Industrial and consumer glues, in the veterinary glues and in medical applications.

Silylated Polymer Adhesives

Technology

Moisture curable Silylated Adhesives & Sealants are

a part of these last years’ recent developments. Silane-modified adhesives and sealants based on SMP (Silane modified polymer) are designed as onecomponent systems. a part of these last years’ recent developments. Silane-modified adhesives and sealants based on SMP (Silane modified polymer) are designed as onecomponent systems.

Bonding process

SMP adhesives have to be applied from 5°C to 30°C and bond within 10-30 minutes by reaction with air humidity.

Applications

Due to their chemical structure these kind of polymers exhibit good weathering and aging resistance as well as an almost universal adhesion spectrum without need of primers. They excel where elastic construction joints are required

Silicone Adhesives

Technology

Silicone adhesives are based on Polysiloxanes chemistry which allows high flexibility even at low

temperature as well as  humidity and temperature resistance. They are available in one or two humidity and temperature resistance. They are available in one or two

components systems.

Bonding process

Both systems cure by polycondensation initiated by moisture for the one component system and by reaction of a silicic acid ester with polysiloxane for the two components system.

Applications

Silicone adhesives give moisture resistant bonds

for glass and ceramics therefore is mainly used for

sealing joint in sanitary application.

|

|